Steel ball valves from LD are crucial components in the industry with a wide range of applications. They are used for controlling and regulating the flow of liquids and gases across various sectors. This article discusses the advantages, main components, types, and applications of LD steel ball valves, along with recommendations for selection, installation, and maintenance.

ADVANTAGES OF LD BALL VALVES

LD steel ball valves offer several benefits, including quick delivery, making them a popular choice in the industry. Firstly, they are highly reliable and durable due to their steel construction. They can withstand high pressures and temperatures, making them ideal for aggressive environments. Additionally, LD steel ball valves have a broad range of applications and are used in various industries, including oil and gas, chemicals, food processing, and many more. Another advantage is their ease of use and maintenance.

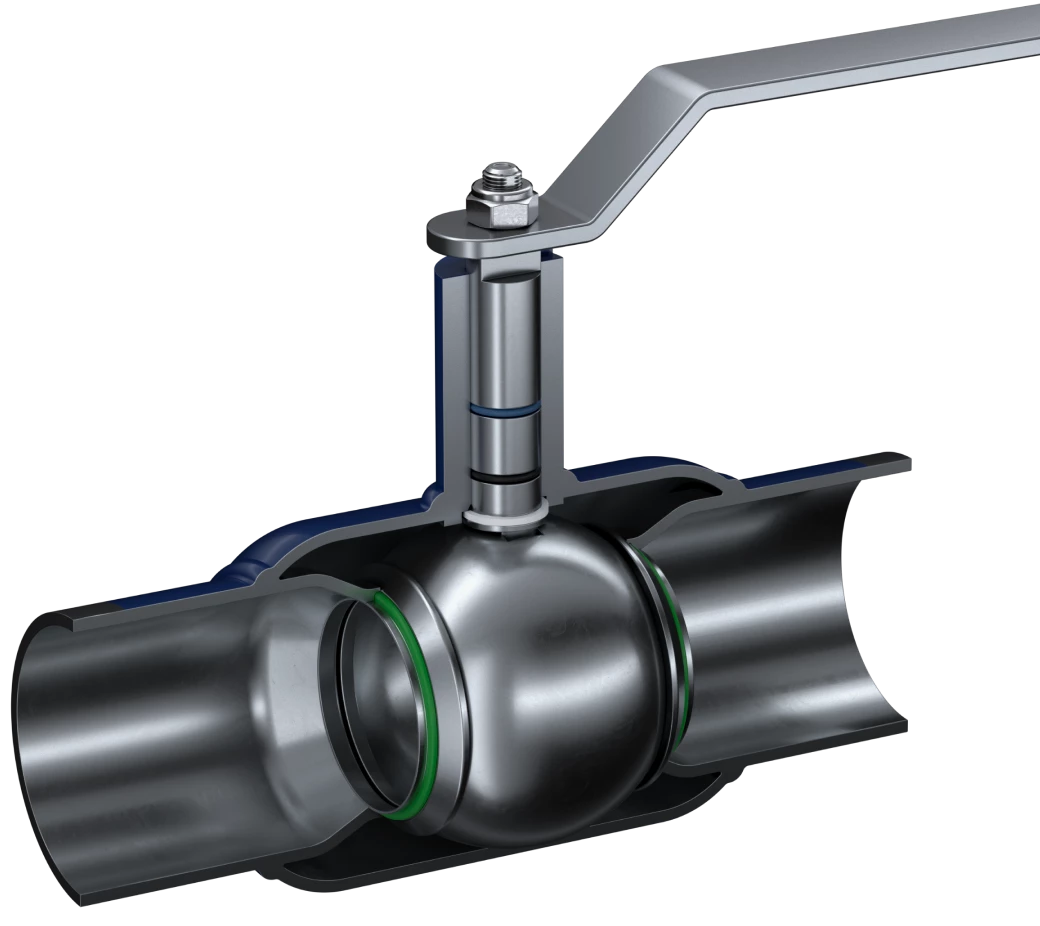

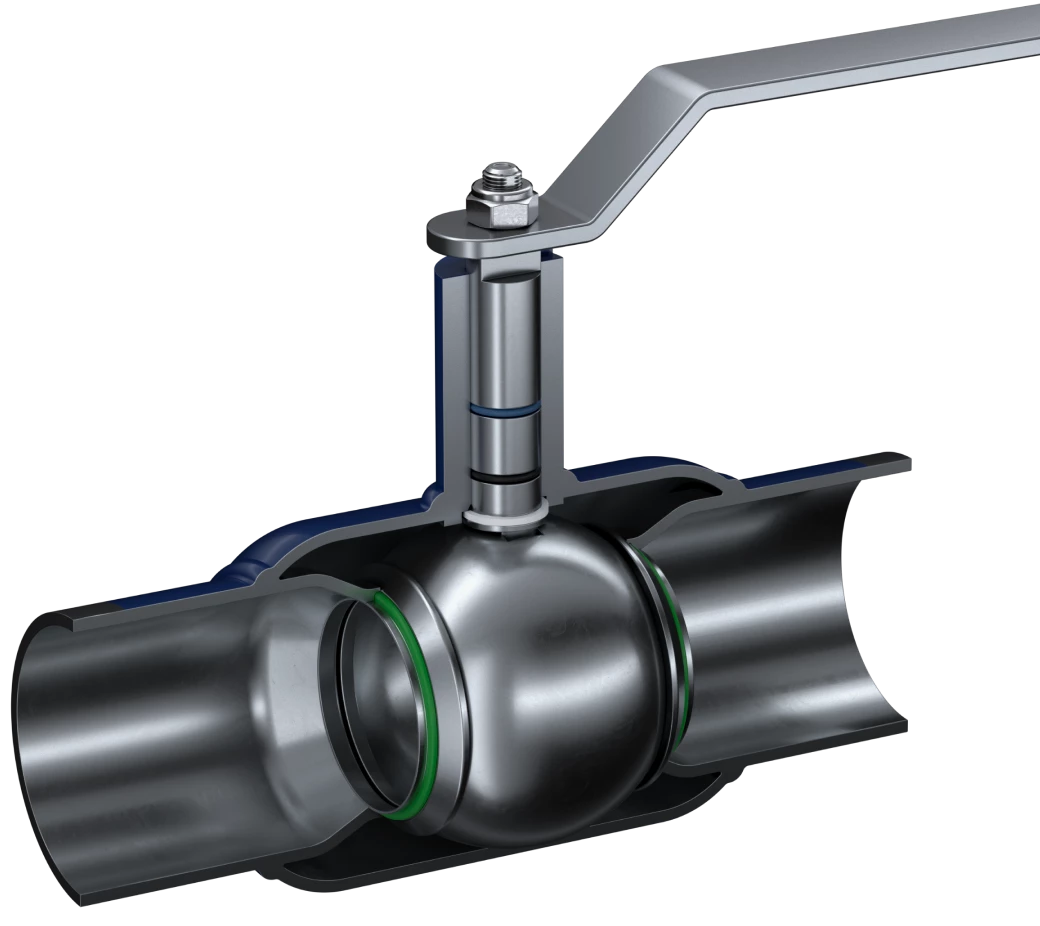

MAIN COMPONENTS OF LD STEEL BALL VALVES

LD steel ball valves consist of several key components. The outer body of the flanged valve protects internal parts and ensures operational reliability. A key component is the ball plug, which controls the flow of liquid or gas. Seals and gaskets ensure connection tightness and prevent leaks. Handles and actuators control the operation of the valve.

VARIOUS TYPES OF STEEL VALVES

LD steel ball valves are available in different options - manual and automatic operation valves, as well as valves of various diameters and pressures. This allows for selecting the most suitable valve type based on specific requirements and operating conditions.

APPLICATION EXAMPLES

LD ball valve applications include residential utilities, heating systems, and refineries. They work efficiently with district heating water, various oil products, petroleum products, and other liquids without abrasives. Operating temperature ranges from -40°C to +200°C.

RECOMMENDATIONS FOR SELECTION AND INSTALLATION

When selecting and installing LD steel ball valves, consider several factors. First, calculate operational parameters such as pressure, temperature, and type of medium. Based on these, you can select the appropriate valve type. When installing the valve, follow the manufacturers instructions and ensure a correct connection with other system elements. Additionally, regular maintenance and inspection will help keep the valve in good working condition, extend its service life, and provide easy access for flow adjustments.

CONCLUSION

LD steel ball valves are reliable and robust components widely used in industry for controlling liquid and gas flows. They have several advantages, including resistance to aggressive environments and ease of operation. Choosing the right valve type, such as flanged or with a gearbox, correct installation, and regular maintenance are important factors for effective valve operation. LD steel ball valves play a significant role in various industries and are an essential part of many processes and systems.

Steel ball valves from LD are crucial components in the industry with a wide range of applications. They are used for controlling and regulating the flow of liquids and gases across various sectors. This article discusses the advantages, main components, types, and applications of LD steel ball valves, along with recommendations for selection, installation, and maintenance.

ADVANTAGES OF LD BALL VALVES

LD steel ball valves offer several benefits, including quick delivery, making them a popular choice in the industry. Firstly, they are highly reliable and durable due to their steel construction. They can withstand high pressures and temperatures, making them ideal for aggressive environments. Additionally, LD steel ball valves have a broad range of applications and are used in various industries, including oil and gas, chemicals, food processing, and many more. Another advantage is their ease of use and maintenance.

MAIN COMPONENTS OF LD STEEL BALL VALVES

LD steel ball valves consist of several key components. The outer body of the flanged valve protects internal parts and ensures operational reliability. A key component is the ball plug, which controls the flow of liquid or gas. Seals and gaskets ensure connection tightness and prevent leaks. Handles and actuators control the operation of the valve.

VARIOUS TYPES OF STEEL VALVES

LD steel ball valves are available in different options - manual and automatic operation valves, as well as valves of various diameters and pressures. This allows for selecting the most suitable valve type based on specific requirements and operating conditions.

APPLICATION EXAMPLES

LD ball valve applications include residential utilities, heating systems, and refineries. They work efficiently with district heating water, various oil products, petroleum products, and other liquids without abrasives. Operating temperature ranges from -40°C to +200°C.

RECOMMENDATIONS FOR SELECTION AND INSTALLATION

When selecting and installing LD steel ball valves, consider several factors. First, calculate operational parameters such as pressure, temperature, and type of medium. Based on these, you can select the appropriate valve type. When installing the valve, follow the manufacturers instructions and ensure a correct connection with other system elements. Additionally, regular maintenance and inspection will help keep the valve in good working condition, extend its service life, and provide easy access for flow adjustments.

CONCLUSION

LD steel ball valves are reliable and robust components widely used in industry for controlling liquid and gas flows. They have several advantages, including resistance to aggressive environments and ease of operation. Choosing the right valve type, such as flanged or with a gearbox, correct installation, and regular maintenance are important factors for effective valve operation. LD steel ball valves play a significant role in various industries and are an essential part of many processes and systems.